Products

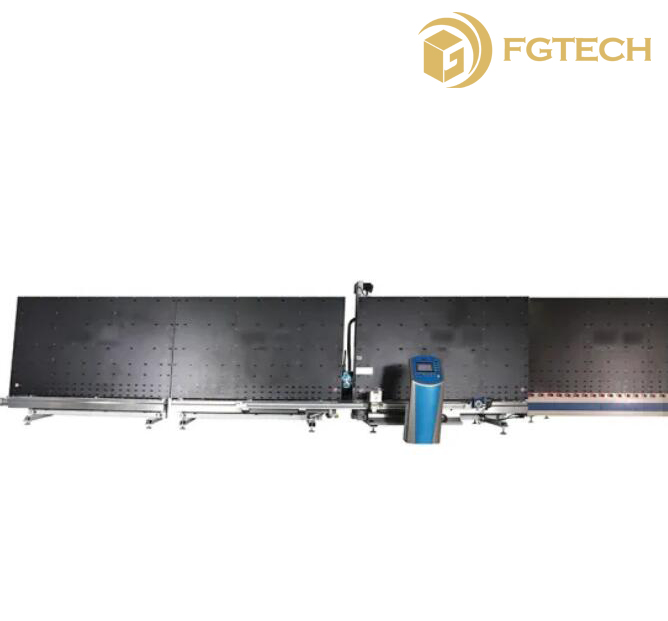

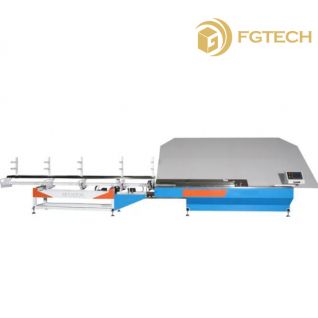

Two-Component Sealant Coating Machine for Double Glazing Glass

The machine mixing system uses a power-assisted suspension device to reduce the labor intensity of workers.

Basic Info.

1.High-efficiency two-component gluing machine ,the main motor ,auxiliary motor and safety protection valve are all manufacture by HASCO original process,supplemented by key machine manufacturing parts ,which are made of high-strength substitute stainless steel by heat treatment process,so that the two -component glue is applied ,the reliability and durability of the machine are greatly improved ,ensuring the excellent quality of the equipment .

2.It is adopt stainless steel reciprocating belt mixer ,working resistance is not small ,the amount of the glue is large ,plastic glue is cleaned ,easy to clean ,no leakage phenomenon ,and the lightest weight

3.The machine mixing system uses a power-assisted suspension device to reduce the labor intensity of workers.

4.The B component system uses low pressure filtration to remove impurities into the high pressure system and improve the reliability of the machine .

5.Compared with the hydraulic type ,the machine has a fast dispensing speed and a low failure rate .and can be used to flush the glue gun during power failure.

| Machine dimensions | 1100x900x1600mm |

| Max size | 1300x2400mm |

| Weight | 550kg |

| AIr pressure | 0.5-0.8Mpa |

| A charging barrel | 55/ 560mm |

| B curing barrel | 5/ 280mm |

| Max air consumption | 1.2m3/min |

| Max ratio | 6:1-14.1 |