Products

Jdpe Bubble Film Making Machine

The low density polyethylene (LDPE) with melting index MI=2~7 is used as the main raw material in the bubble film machine.

Basic Info.

The low density polyethylene (LDPE) with melting index MI=2~7 is used as the main raw material in the bubble film machine. The linear raw material (LLDPE) with melting index MI=1.0~1.5 can be added in proper proportion, and the regenerated LDPE with melting index equivalent to MI=2~4 can be partly or completely used as the raw material so as to make bubble film of a certain width.

Because the air bubble film, is filled with air, it is light, transparent, flexible with sound insulation, anti-vibration and anti-wear performance, which is widely used in electronic, instrumentation, ceramics, handicrafts, household appliances, bicycles, kitchens, furniture and lacquer products, glass products and precision instruments and other antiknock cushioning packaging. It can be made into bubble bags, envelope bags, etc.

| Model | Qty | Price |

| JDPE-2000 Air Bubble Film Making Machine Video: https://youtu.be/ysQNWnmPZ2k |

1 Set | 39,000USD |

| Possible Accessories: | ||

| Cooling Tower-30T (Suggest Buy in local) | 1 Set | 1200USD |

| Edge Online Recycle(Not Suggest) | 1 Set | 3,100USD |

| Filter Change to Hydraulic | 1 Set | 2,200USD |

| Total | 1 Line | |

- Working Process

Extrusion→Bubble Forming→Trimming→Winding.

- Main Datas

| Model | JDFPE-2000 |

| Screw Diamter | Φ90 |

| L/D | 30:1 |

| Forming Roller | Φ270mm; Bubble:Φ10*2.8 or Custermize |

| Finished Film Width |

1600-2000mm |

| Forming Thickness |

30-120gsm |

| Usable Material | LDPE,LLDPE |

| Max Working Speed: |

18-25 m/min |

| Max Extrusion Capaciy: |

150kg/h |

| Motor Power |

45 kw |

| Total Power |

123kw |

| Winding Diameter | ≤φ1400 mm |

| Weight |

9t |

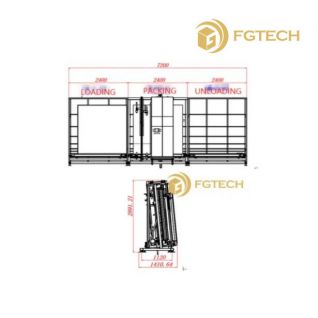

| Overal Demensions | 10000×5500×3500 mm |

| Power Supply | 380/3/4/50(Volt/Ph/Line/Hz) |

Note: Due to the continuous improvement of the products, the appearance and technical parameter subject to change without notice. Meanwhile, we can customize machines of different levels of specification for customers.

Other Data:

1,Machine speed:Max 28m/min,Detail Real speed by material and forming thickness.

2,Roller Width:2100mm

3,Extrusion Material:LDPE / LLDPE

4,Extrusion Variation:±5%

5,Heating:Electrical Heating

6,Temperature Control:Temperature Controller

7,Drive Motor:AC Drive Converter Motor

8,Converter:AC Drive Frequency Converter

9,Power Require:Loading Power 123kw(Using power around 60~85kw)

10,Cooling Water:16~25ºC

- SJ90/30 Single Screw Extruder 1Set

2,Filter and Connector 1Sets

3,T-Die 1Sets

4,Extruder and T-Die Heating Control 1Sets

5,Forming 1Set

6,Traction 1Set

7,Winder 1Set

8,Control System 1Set

9,Protection

- SJ90/30 Single Screw Extruder 1Set,

Screw and Barrel:

1)Dia:φ90mm,L/D 30:1

2)Material:38CrMoAlA

3)Treating:Nitrogen Treatment and Hard Chrome Plating

4)Nitrogen:0.4-0.7mm

5)Heater:Ceramic Heater

6)Heating Power:37.5kw

7)Heating Zone:5 Zones

Gear Box: 1Set

1)Speed Reduction: 12.5/10

2)Forced Oil Circulation

Hopper:With Inner Water Circulation Cooling

Speed Control:Frequency Converter(Weichuang)

Drive Motor:45kw

RPM:5-95rpm

2,Filter And Connection 1Sets

Type:Manual Net Changer

Material:38CrMoAlA and 5CrNiMo

Heater: 1)Heating Type:Heating Circle;

2) Heating Zone: 1

3,T-Die

Model:BJ-2100

Working Width:Lip 2100mm;Gap 0-1.5mm(0.8mm EXW)

Material:A1.2133(German),NM Level Hard Chrome plated.(High toughness,Acid proof and rust proof,reduce Sticky)

1