Products

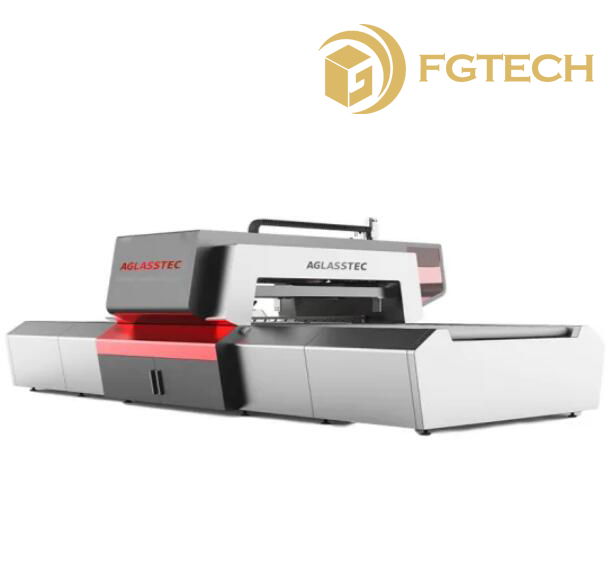

6170*3943*1800mm Best Quality Customized Double Glazing Glass Seaming Production Line Project Fge-Hf2000

The machine use rubber rob wheel to press glass, transmission of fixed glass, processing and milling to avoid glass scratches and can effectively deal with Low-E glass in addition to film, edging processing problems.

Basic Info.

FGE-HF2000 Glass Seaming Porduction line

* Suitable for high-speed processing for hollow glass architectural glass, doors and windows glass, white glass and low-E glass. The machine use rubber rob wheel to press glass, transmission of fixed glass, processing and milling to avoid glass scratches and can effectively deal with Low-E glass in addition to film, edging processing problems.

*The machine adopts automatic interface operation, PLC control, intelligent fast response servo system, intelligent computer controls high speed, precision transmission glass transmission system; high speed grinding processing structure, shuttle angle processing speed of 35m/min, automatic identification of glass size. Accurate positioning, different specifications of the glass can be continuous on the film, without manual adjustment of the whole positioning, the entire process by the rubber stick pressure roller wheel position accurate, the product diagonal size is accurate, the control system has my diagnostic function, can master a variety of job information.

*The machine can be followed by automatic connection, automatic horizontal drilling machine, washing machine, steel furnace and other equipment composed of automatic glass processing production line, is the building hollow glass edging processing the strongest supporting equipment.

I.TECHNICAL PARAMETER FOR SEAMING MACHINE

| Machine dimension | 6170*3943*1800mm |

| Grinding speed | 25-35m/min |

| Max processing sizes | 2000*3600mm |

| Min processing sizes | 300*650mm |

| Processing glass thickness dimensions | 4-10mm |

| Chamfer width | 45 degree |

| Worktable standard height | 900mm |

| Spindles | 3 pcs |

| Total power | 14.5 KW |

| Machine total weight | 5 tons |

II.TECHNICAL PARAMETER FOR WASHING MACHINE

-

- Max. Glass Width: 2000mm

- Min. Glass Size:400mm*400mm (limit to put glass from left and right sides in single row)

- Glass Thickness:3mm-25mm (digital display)

- Speed Range: Vmax=1-12m/min (glass thickness within 3-25mm)

- Rubber Roller and Brush Roller Speed: frequency adjustment.

- Working Height: (900±25)mm

- Total Power:35KW

- Water Source: circulating water,city water, and deionized water ( Buyers need to prepare deionized water equipment by themselves. )

- Power Supply: 380V, 50HZ

- Machine Dimension (L*W*H): 5500*4000*2840mm

(Packing Size: 1.2120×3100×1200mm,1Pcs; 2. 3100X1660X2200, 1Pcs; 3.1700×1200×1400mm 1Pcs; 4.2400×500×400, 1Pcs; 5. 1200X180X1640 2Pcs; 6.4000X180X180, 2Pcs.)

III.WORKING CAPACITY

Single side arris |

Range of Chamfer Width(mm) | Grinding Speed (m/min) | Productivity for 1000*1000 size (pcs / hour) | Productivity for 2000*2000 size (pcs / hour) | Productivity for 1550*520 size (pcs / hour) |

| 0-2 | 25-35 | 180-200 | 160-180 | 170-190 |