Products

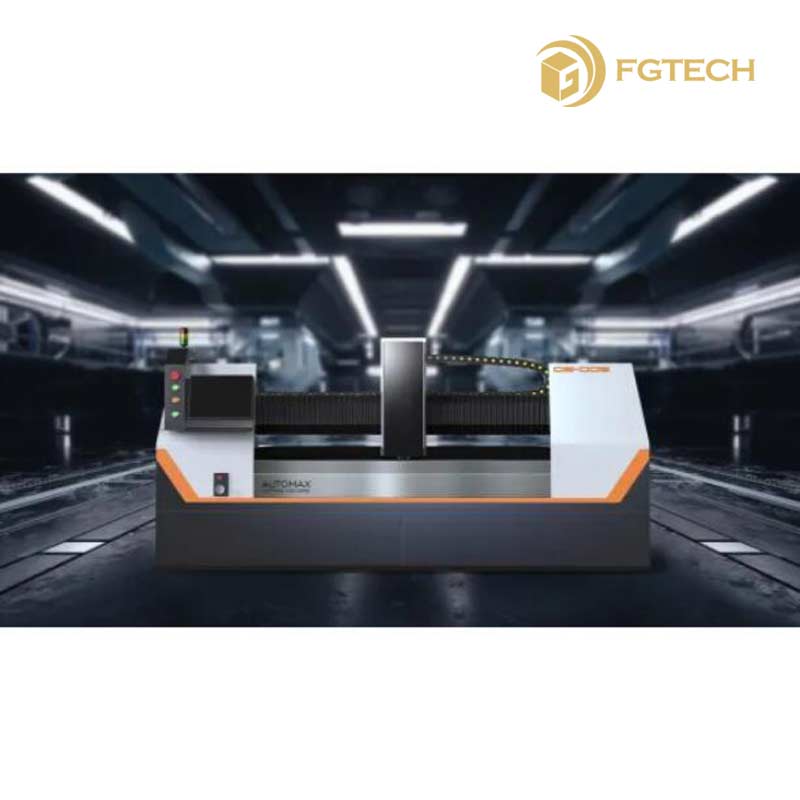

2021 Best Selling Industrial Aluminum Panel or PVA Glass CNC Machine Fgd-Hw2010c

Product ID : FGD-HW2010C

Product Attributes :

CNC control system:Four axis control, remote collaboration function

Product Description

Basic Info.

Model NO.

FGD-HW2010C

Grinding Head Number

10

Condition

New

Working Table Size

2200X1200mm

The Max. Weight Load

100kg

Material

Industrial Aluminum Panel or PVA

Grinding Speed Range

1-15m/Min

Max. Rough Grinding Speed

15m/Min

Max. Fine Grinding Speed

15m/Min

Max. Polishing Speed

8m/Min

CNC Control System

Four Axis Control, Remote Collaboration Function

Water Ring Vacuum Pump

2.2kw

Maximum Negative Pressure

- 0.093MPa

Installation Parts

One Set of Tools, One Set of Manual Book

Total Power

15kw

Total Weight

3600kg

Spindle Cooling Mode

Recycle Water Cooling

Trademark

AGLASSTEC

Transport Package

Suitable for Sea Transportaiton

Specification

3900*2300*1800mm

Origin

China

HS Code

8464901900

Technical Parameters

| CNC GLASS CENTER SPECIFICATION |

| Work Table Size:2200X1200 |

| Grinding speed Range:1-15m/min. Max. Rough Grinding Speed: 15m/min; Max. Fine Grinding Speed: 15m/min; Max. Polishing Speed: 8m/min |

| The CNC can realize automatic tool switching in multiple working procedures including grinding round edge and straight edge. |

| The vacuum cup is made of high-quality rubber. Equipped 10 pcs vacuum cup with machine. |

| Positioning pile using pneumatic positioning is accurate and reliable. One machine equipped with 8 sets of positioning piles. |

| DB polishing wheel can automatically compensate electric pressure, wheels compensation automatically. |

| CNC control system:Four axis control, remote collaboration function |

| Delta servo motor and servo drive. |

| Delta high-speed spindle frequency conversion drive & frequency converter. |

| Linear guide rail and ball screw adopt Taiwan TBI or HWIN products, which has automatic electric oil pump for lubrication, and the screw has double nuts. |

| High speed variable frequency spindle which is water cooling, and max. speed :9000RPM if for home-appliance glass. Tool swift is pneumatic control. |

| Water ring vacuum pump 2.2kw , maximum negative pressure - 0.093mpa |

| The flexible part of the cables use the special towing cable for cnc machine |

| Machine table use the thickened industrial aluminum plate. |

| Machine protection cover and water tank use stainless steel |

| Installation parts: one set of tools, one set of manual book. |

| Onsite installation and training, 3 days. Maintenance training, one day. Operation training, two days. |

| Total power is 15KW. Dimension of equipment: 3400X2300X1800mm total weight 3600KG. |

| CNC GLASS CENTER CONFIGURATION | |||

| Travel Distance | X-axis | 1800mm | |

| Y-axis | 1100mm | ||

| Z-axis | 100mm | ||

| Distance from Spindle to Working Table | 100mm | ||

| Glass Thickness | 4-10mm | ||

| Accuracy | Positioning accuracy | ±0.05 | |

| Repeat accuracy | ±0.03 | ||

| Machine Weight and Power | Weight | 4.2 tons | |

| Installation Power | 15kw | ||

| Machine Size | 3900*2300*1800 | ||

| Air Source | 0.6mpa, 0.3sqm/hour | ||

| Water Supply | 60L/min | ||

Working Table |

Working Table Size | 1700X1200mm | |

| The Max. Weight Load | 100KG | ||

| Material | Industrial Aluminum Panel or PVA | ||

| Machine Frame | Machine frame is welded by 210*150mm steel square tube, and designed with obliquity for water flow. |

| Machine Frame | Machine frame is welded by 210*150mm steel square tube, and designed with obliquity for water flow. |

| Machine beam is welded by 300*200*10mm steel square tube | |

| Machine frame and beam did anneal treatment, and VSR treatment | |

| Waterproof and Protective Panel | Working Table is surrounded by stainless steel protective panel |

| Beam top and bottom also have stainless steel protective panel | |

| There are SS oil groove of guiderail of Y axis to avoid rusting after long time working which will affect the accuracy | |

| There are alarm panel in orange color beside at two side of the machine | |

| The machine equipped with stainless steel water tank. | |

| There are water proof panel on X axis and Y axis | |

| Electric and Pneumatic Control System | CNC control system, four axis control, remote collaboration function |

| Servo motor and servo drive use product from Delta | |

| High speed spindle is frequency drive and use Delta Inverter | |

| Industrial computer uses I5 processor | |

| Displayer is 18.5-inch LCD | |

| Intermediate relay is from products from Schneider | |

| Power supply switch is also from Schneider | |

| Sensors are from Omch or Omron | |

| 4 axis hand wheels | |

| Signal lamp installed to show machine running status | |

| The system has voltage compensation function or linear compensation function | |

| Drawing software with processing program generation function | |

| The system has function of adjusting polishing wheel | |

| The system has function of adjusting leveling of working table | |

| Spindle | Spindle motor rotating speed is 2000-9000Rpm |

| Spindle Motor: 7.5kw | |

| Spindle Sealing Mode: pneumatic sealing |

| Spindle Cooling Mode: Recycle water cooling | |

| Spindle handle use BT40 and with locking base | |

Online Inquiry